First,Overview

-

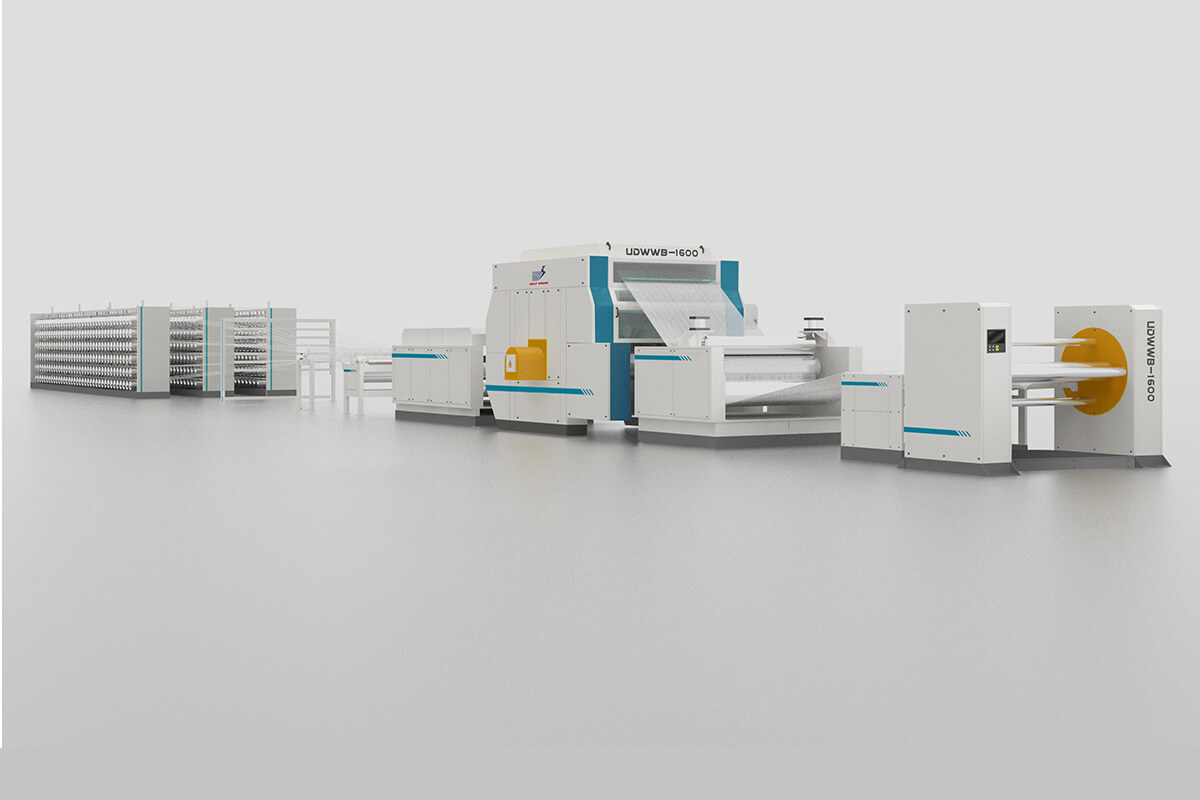

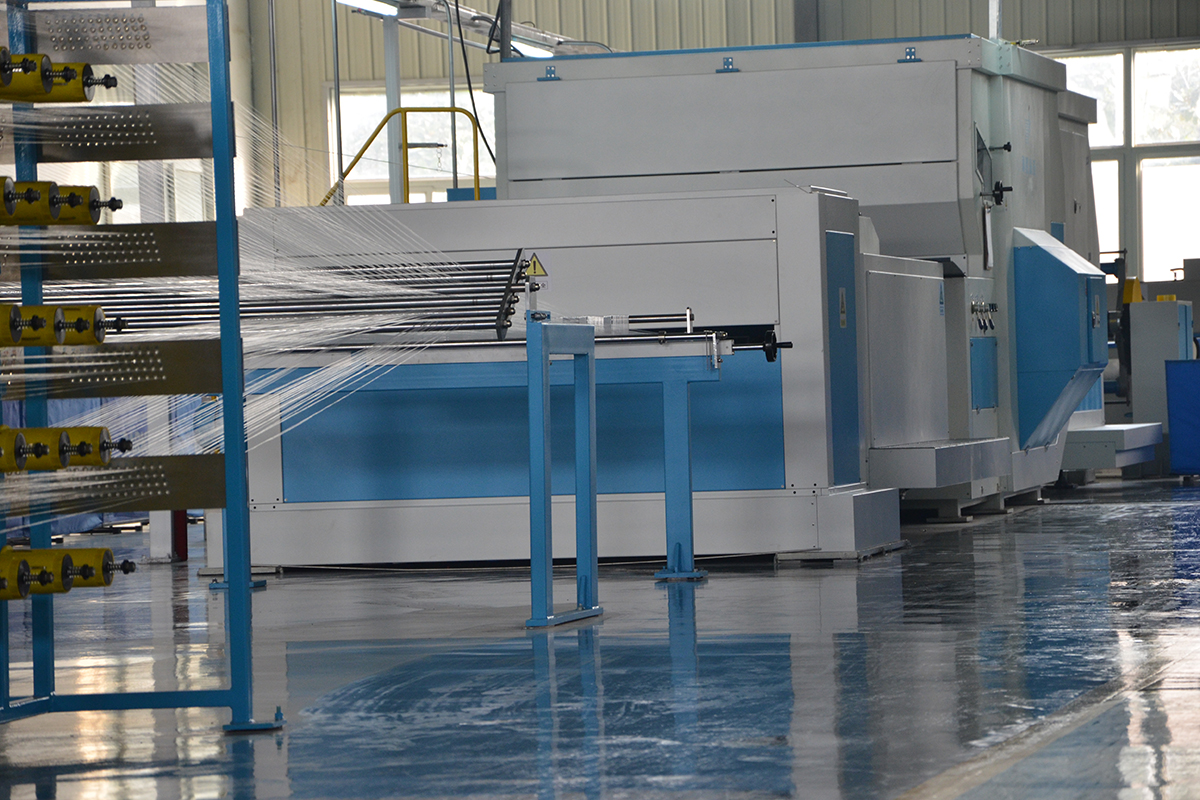

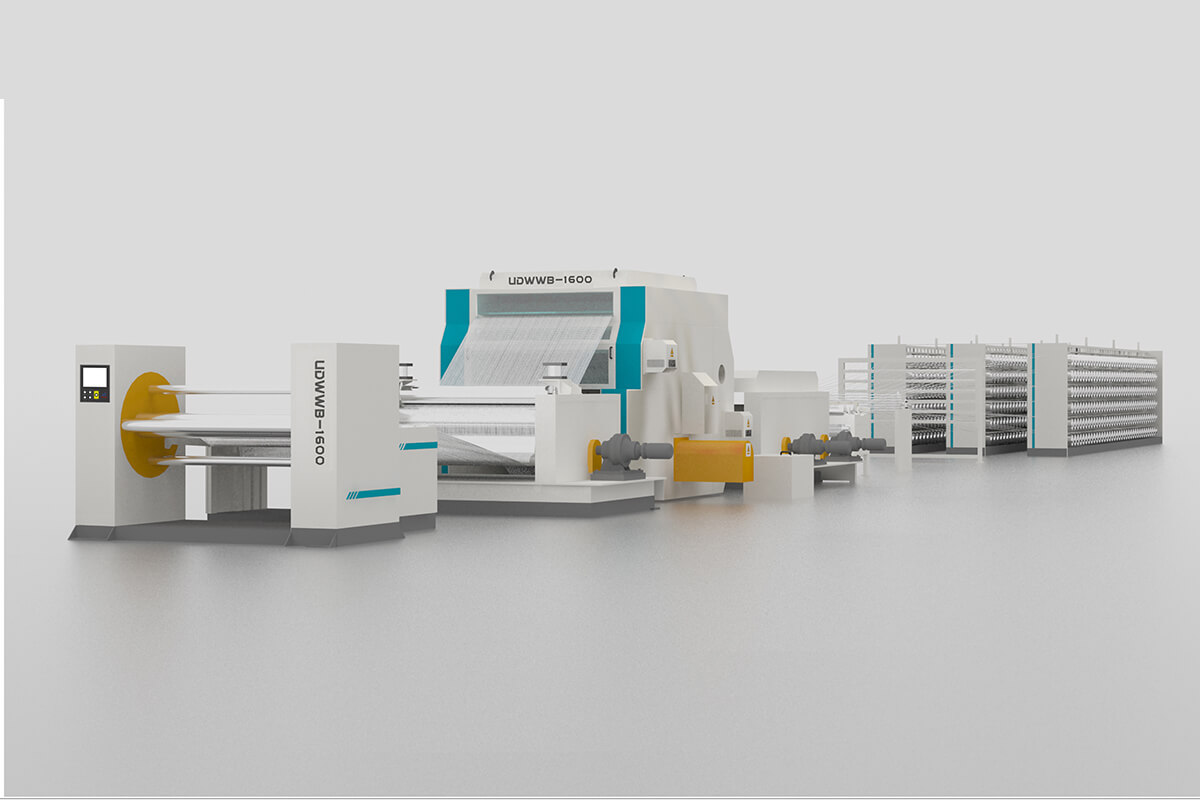

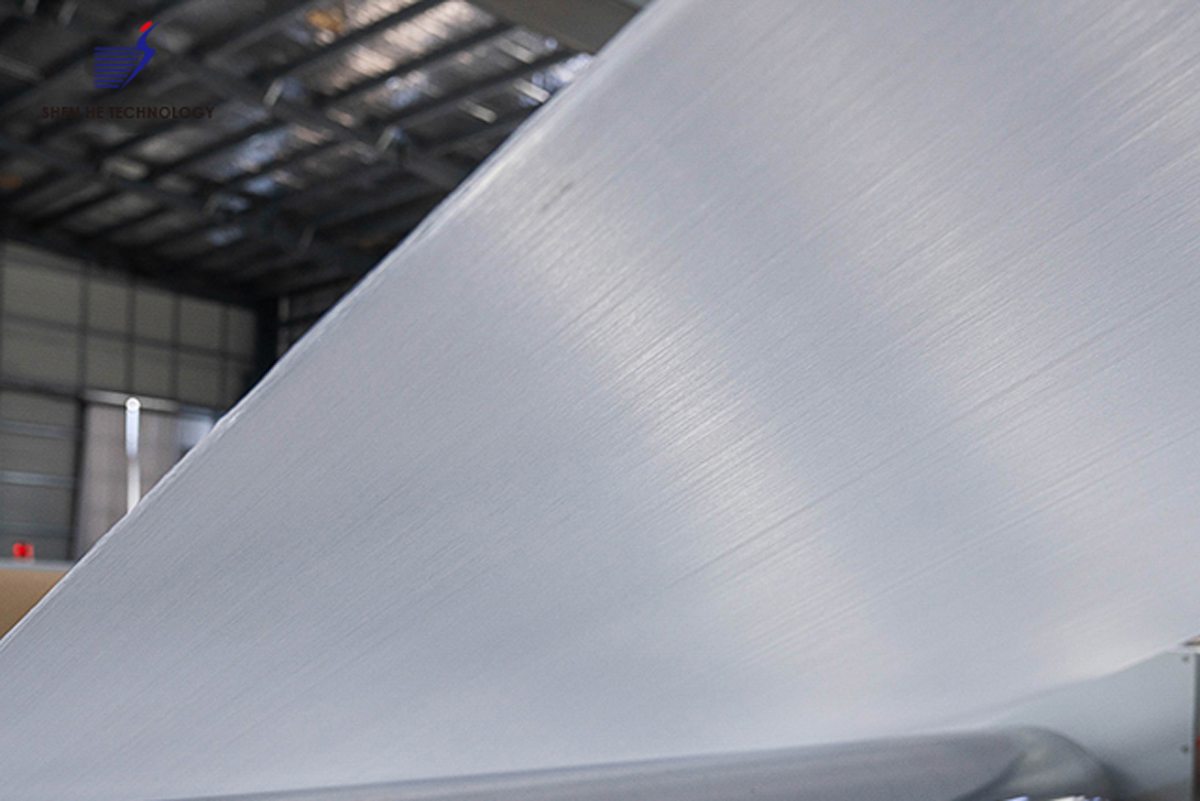

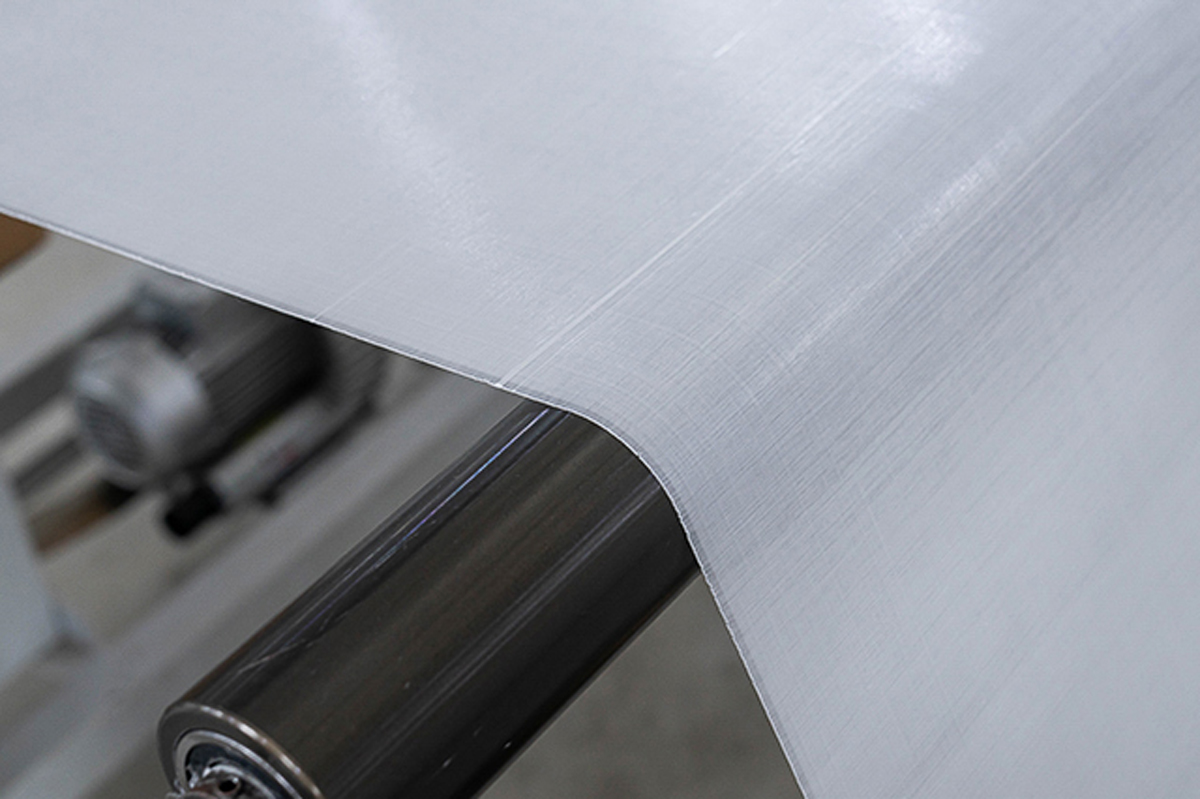

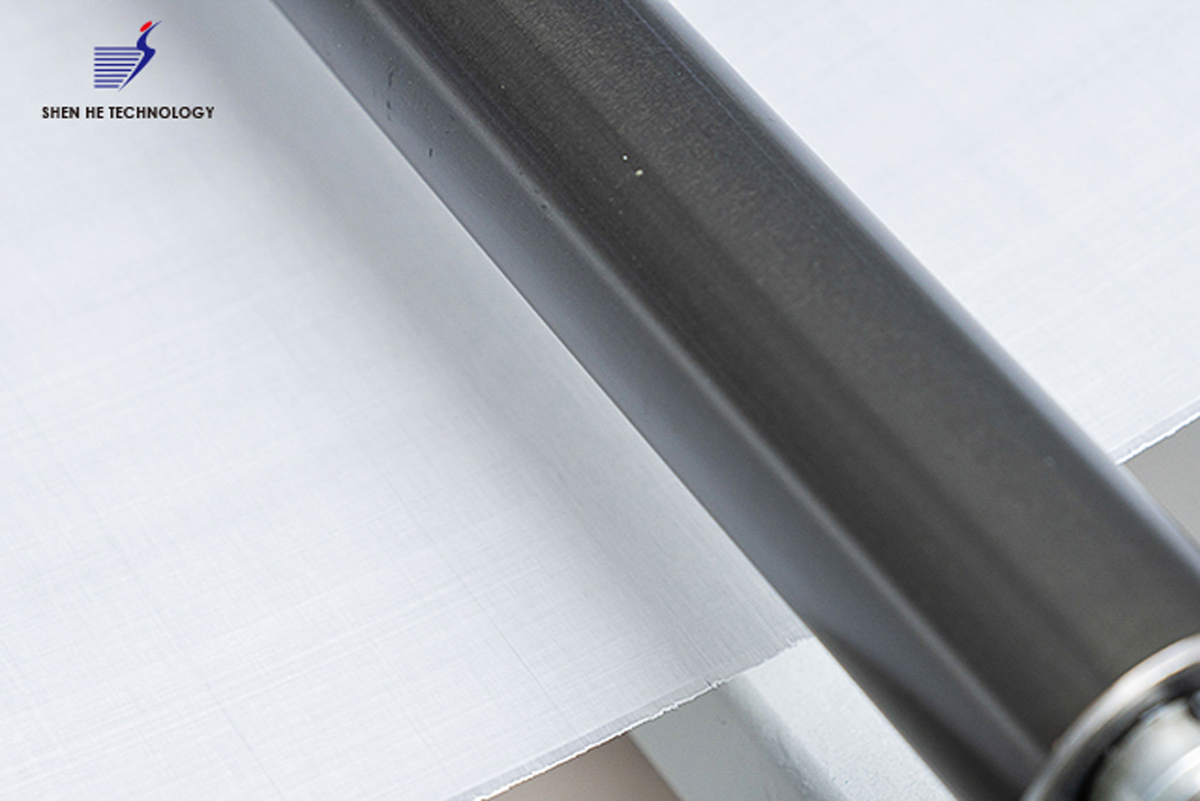

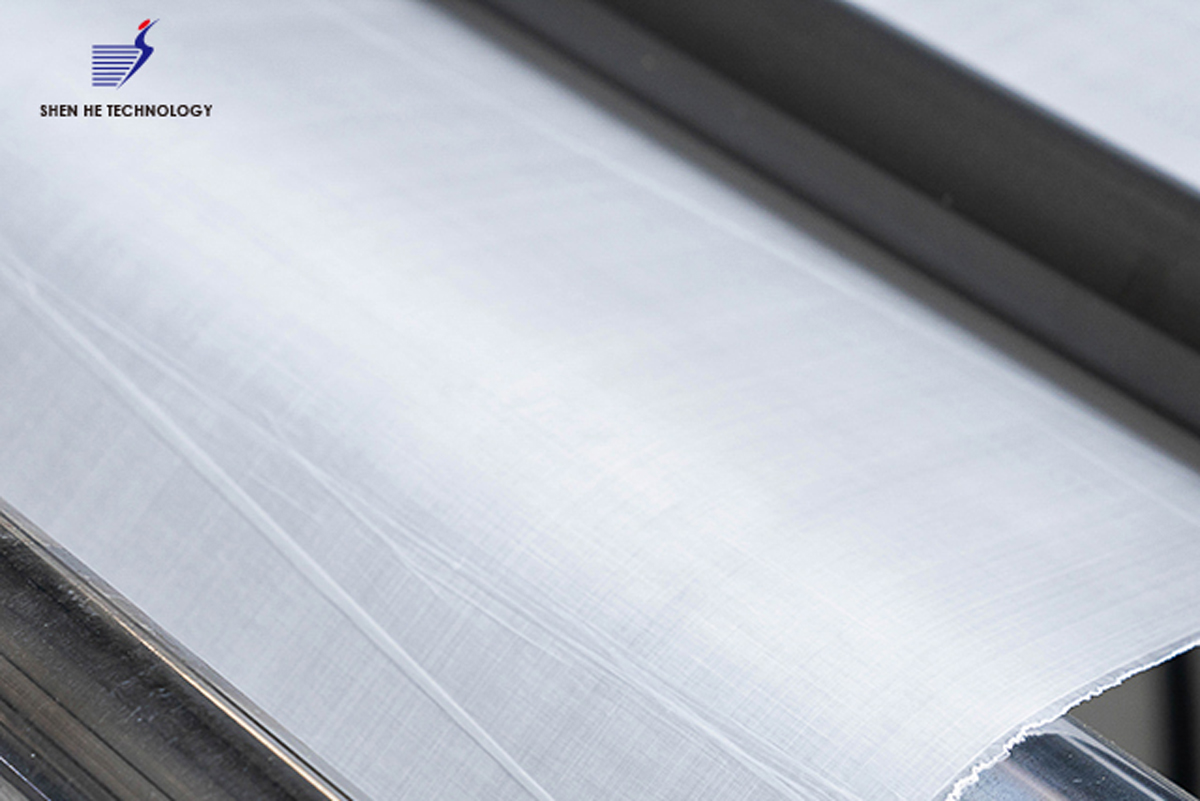

The continuous UD weft-free complete set production line developed and manufactured by our company has greatly improved the lightness and elasticity of the UD sheet through unique substrate material balance treatment, excellent tow arrangement structure, and the use of water-based dispersion adhesive. Achieve continuous and uniform wire laying and ensure a uniform areal density.