-

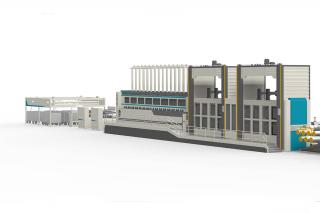

System introduction

Bundle: Parallelly and uniformly pull out the gelatin tow after standing.

Pre-drawing: The pre-tensioned jelly filaments drawn from the bundle are fed into the extraction process smoothly after applying pre-tension in parallel.

Extraction: The solvent inside the frozen collagen silk is completely extracted in the extraction equipment. Drying: The constant-temperature circulating air is used to dry the extractant on the surface of the tow to obtain the dried raw silk.

Drafting: Three-stage thermal drafting is performed on the dried tow, so that the ultra-high molecular weight polyethylene tow has high strength and high mold mechanical properties. Winding: Untwisted constant tension winding equipment is used to wind and mold the ultra-high molecular weight polyethylene high-strength and high-mold tow.

Inspection: UHMWPE tow is tested for various physical indicators.

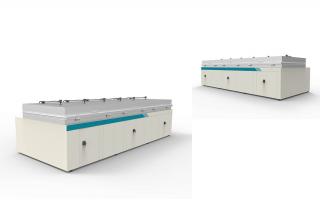

Creel

Quality Creel,After Spinning Production System manufacturers & exporter - buy Creel,After Spinning Production System from China manufacturer.

Tel: 0086-18905100000

E-mail: summer@jsljkeji.com

Engineers capable of providing overseas installation and testing and training. Factory layout design, assembly, installation and commissioning, startup and local team training will be provided free of charge.

• Prompt delivery and flexible payment terms

• Welcome strategic partners

• Professional team with strong technical and R & D knowledge to develop advanced food equipment

• Save labor costs and increase production capacity.

• Prompt delivery and flexible payment terms

• Welcome strategic partners

• Professional team with strong technical and R & D knowledge to develop advanced food equipment

• Save labor costs and increase production capacity.