-

System introduction

Ingredients: Ultra-high molecular weight polyethylene powder is mixed with white oil and antioxidant in a certain proportion, and then uniformly and constant pressure is added to the twin-screw extruder through the pipeline. Spinning: The ultra-high molecular weight polyethylene macromolecular concentrated solution fully dissolved by the twin-screw extruder is accurately measured and extruded from the spinneret hole of the spinning box, and enters the constant temperature frozen water, and the temperature of the raw silk is exchanged by heat exchange. Quickly descend to obtain frozen collagen filaments, and place the frozen collagen filaments in an overlapping and orderly order in a silk bucket. Equilibrium: The solid-liquid phase separation and stress relief balance are carried out in the jelly wire barrel in a constant temperature space for about 24 hours.

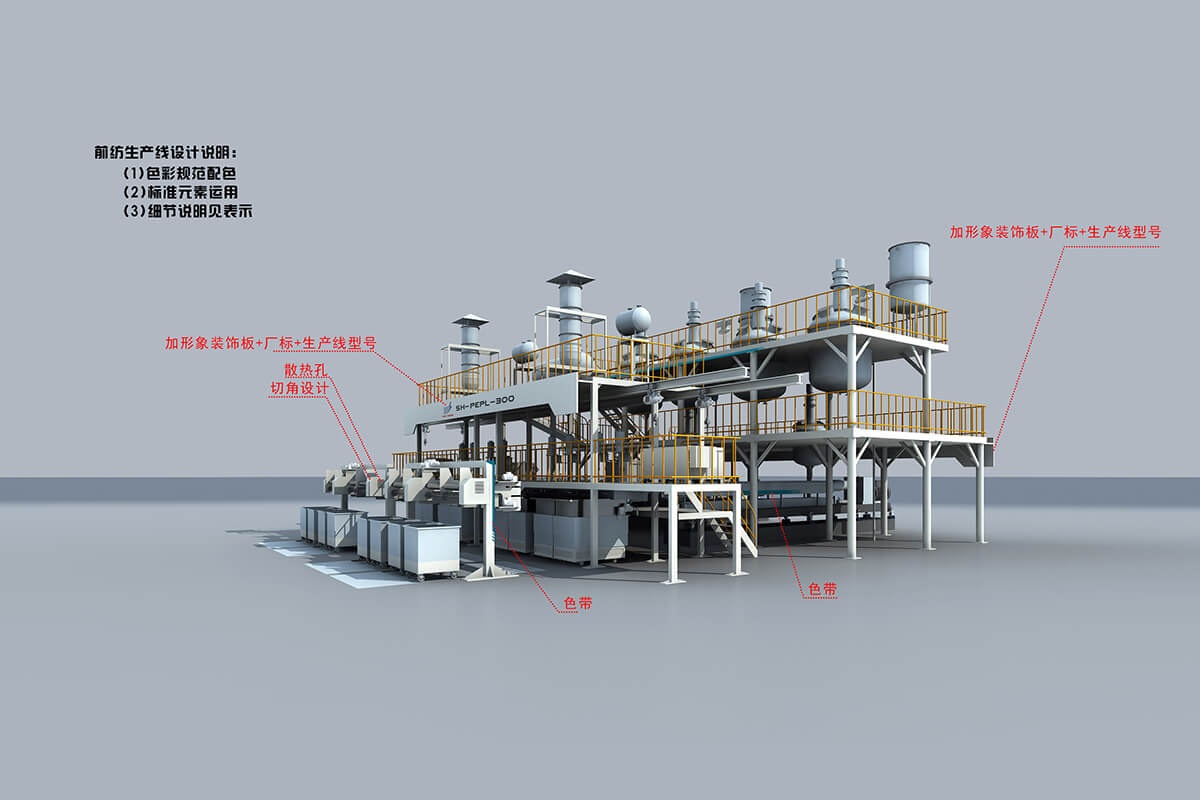

Front Spinning Production System

Jiangsu Shenhe Technology Development Co., Ltd. is the best Front Spinning Production System manufacturer in China. Offering quality product to global customers

Tel: 0086-18905100000

E-mail: summer@jsljkeji.com

Engineers capable of providing overseas installation and testing and training. Factory layout design, assembly, installation and commissioning, startup and local team training will be provided free of charge.

• Prompt delivery and flexible payment terms

• Welcome strategic partners

• Professional team with strong technical and R & D knowledge to develop advanced food equipment

• Save labor costs and increase production capacity.

• Prompt delivery and flexible payment terms

• Welcome strategic partners

• Professional team with strong technical and R & D knowledge to develop advanced food equipment

• Save labor costs and increase production capacity.