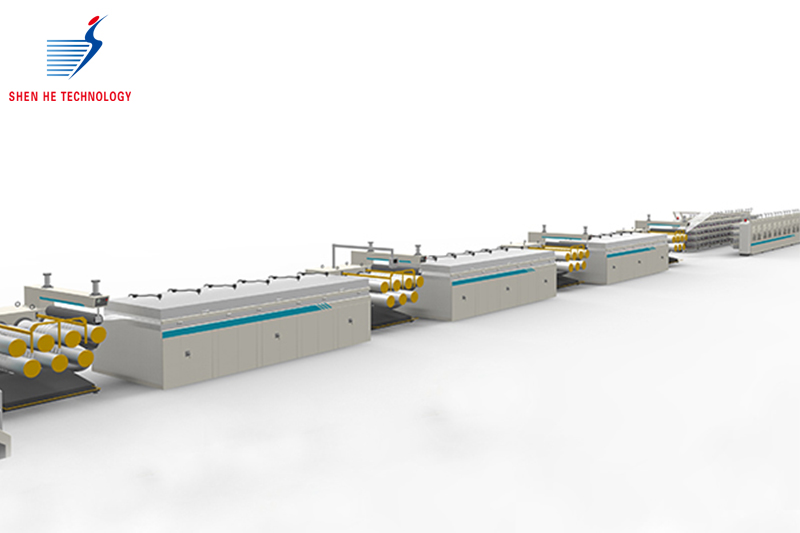

Ultra high molecular weight polyethylene high wear-resistant fiber production line

Jiangsu Shenhe Technology Development Co., Ltd. is one of the toppest Ultra high molecular weight polyethylene high wear-resistant fiber production line in China.During these years of exporting , Jiangsu Shenhe Technology Development Co., Ltd. now has rich experience in the worldwide markets

Tel: 0086-18905100000

E-mail: summer@jsljkeji.com

What is ultra-high molecular weight polyethylene fiber? The full English name of ultra-high molecular weight polyethylene fiber is: Ultra High Molecular Weight Polyethylene Fiber, abbreviated as UHMWPE, also known as high-strength and high modulus polyethylene fiber. It is currently the fiber with higher specific strength and specific modulus Z in the world, spun from polyethylene with a molecular weight of 1 million to 5 million.

Ultra high molecular weight polyethylene high wear-resistant fiber production line

The main properties of ultra-high molecular weight polyethylene fibers

1. High specific strength and high specific modulus. The specific strength is more than ten times that of steel wires with the same cross-section, and the specific modulus is only second to high-grade carbon fibers.

2. Low fiber density, with a density of 0.97-0.98g/cm ³, Can float on the water surface.

3. Low fracture elongation, high fracture work, and strong energy absorption ability, thus possessing outstanding impact resistance and cutting resistance.

4. Anti UV radiation, anti neutron, and γ Radiation has high energy absorption, low dielectric constant, and high electromagnetic wave transmittance.

5. Chemical corrosion resistance, wear resistance, and long flexural life.

Physical properties of ultra-high molecular weight polyethylene fibers:

Density: 0.97-0.98g/cm3. It has a lower density than water and can float on it.

Strength: 2.8-4N/tex.

Modulus: 91-140N/tex.

Elongation: 3.5% to 3.7%.

The impact absorption energy is nearly twice that of aromatic amide fibers, with good wear resistance and low friction coefficient, but the melting point under stress is only 145-160 ℃.

Ultra high molecular weight polyethylene high wear-resistant fiber production line

The main properties of ultra-high molecular weight polyethylene fibers

1. High specific strength and high specific modulus. The specific strength is more than ten times that of steel wires with the same cross-section, and the specific modulus is only second to high-grade carbon fibers.

2. Low fiber density, with a density of 0.97-0.98g/cm ³, Can float on the water surface.

3. Low fracture elongation, high fracture work, and strong energy absorption ability, thus possessing outstanding impact resistance and cutting resistance.

4. Anti UV radiation, anti neutron, and γ Radiation has high energy absorption, low dielectric constant, and high electromagnetic wave transmittance.

5. Chemical corrosion resistance, wear resistance, and long flexural life.

Physical properties of ultra-high molecular weight polyethylene fibers:

Density: 0.97-0.98g/cm3. It has a lower density than water and can float on it.

Strength: 2.8-4N/tex.

Modulus: 91-140N/tex.

Elongation: 3.5% to 3.7%.

The impact absorption energy is nearly twice that of aromatic amide fibers, with good wear resistance and low friction coefficient, but the melting point under stress is only 145-160 ℃.